Blog Archives

What Happened Today at the Monastery?

Another quiet summer day at Kauai Aadheenam, with a steady stream of guests and pilgrims.

Sadhaka Nilakantha returns today from his Sojourn in the World…a discipline followed by all the young sadhaka 3 times during their first twelve years of monastic life. And our silpis and two swamis will be returning in four days time.

Bodhinatha’s latest talk is now on line.

Meanwhile we are happy to announce that the Hinduism Today Digital Edition, (HTDE) October 2007 is now available. Subscribers can simple boot our application and you will be prompted to get the new PDF’s. If you have not loaded HTDE recently, you will be prompted for a special upgrade. Please enter your email address and month of birth exactly as you did when you subscribed. This issue has some very interesting Rich media options, including Thiruppugal songs, and some fascinating audio interviews with Swadhyay youth and more.

Sunil Kakodka performs abhishekam at the Narmada lingam while Manikandan Rangaswamy chants Sri Rudram and Kalpana Patel reverently observes.

Vasundhara joins her husband, Sunil, performing abhishekam.

Sunil first met Gurudeva in 1997 and, after reading Loving Ganesha, he then began studying Gurudeva’s trilogy, Dancing with Siva, Living with Siva and Merging with Siva. He has found the trilogy to be the most deeply profound spiritual study of his life. Both he and Vasundhara continue to absorb these sacred teachings which have been of tremendous importance for them.

Harihar and Kalpana Patel are from New Jersey and are here on their first pilgrimage to the Kadavul Siva temple.

Sunil then bathes Nandi with milk and water.

Manikandan prays after placing a flower on the Siva Lingam which represents Parasivam, the formless aspect of God Siva.

Our foray into new slide show formats continues with the help of iView Software (now known as “Expressions”) that allows you to pull together photos, movies and captions into a mini-web site in “the blink of an eye.”

Enjoy today’s show that Paramacharya Palaniswami has assembled from pictures sent from India:The Carving of San Marga’s Hanuman!

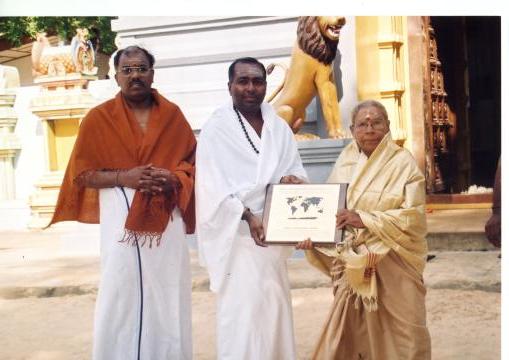

Hindu Renaissance Award Given to Sri Lankan Saivite Leader

Dr. Thangamma Appakutti receives the Hindu Renaissance Award.

Rishi Thondunathan handing over to Dr. Thangamma Appakutti the Hindu Renaissance Award plaque in front of the Sri Thurgai Amman Temple in Thellippalai, Jaffna on August 13th. The Award is presented by Satguru Bodhinatha Veylanswam from Hinduism Today and Kauai Aadheenam for her five decades of religious leadership to Sri Lankan Saivites. Also in the photo is Sri Aru Thirumurugan a well known Saivite leader in Sri Lanka.

The Hindu Renaissance Award plaque says:

“Presented by Hinduism Today to Dr. Thangamma Appakutti for her five decades of religious leadership of Sri Lankan Saivites. A brilliant speaker, her spiritual talks at the home and abroad have been instrumental in inspiring the community to maintain their Hindu heritage and identity. A visionary who trained many to follow in her footsteps, she has founded enduring institutions to help sustain Saiva dharma for generations to come.”

Our Two Swamis in India

Our traveling swamis bring you another batch of photos from their trip.

Here we are at satsang at the home of Sheela Venkatakrishnan in Chennai, the day of our arrival in India.

On August 26, we visited Swamimalai where the middle course of the avudaiyar (base for the sphatika Lingam) for Iraivan Temple was to be cast. Here is a full scale model in cement, created by our temple sthapati, Selvanathan.

This is the mold for the middle course, set in the ground, ready to be heated up.

Here are some of the clay melting pots that are used for the metal. In the middle is a big fire pit that they will be placed into to heat up.

This is the mold for the top course of the avudaiyar. It’s upside down.

Kuberan Sthapati explains to Yoginathaswami and Selvanathan Sthapati exactly how the casting will work and how the three pieces will be put together.

The mold is heated up to 700° so that it does not crack when the 1,000° molten metal is poured in. This is done by placing hot coals, coconut husks and dried cow dung into the mold, which will burn for two hours.

Wire is tightened around the outside of the mold to reinforce it and make sure it will contain the molten metal.

(left to right) Ponni Selvanathan, Selvanathan Sthapati, one of the metal sthapatis, Yoginathaswami, Senthilnathaswami and Selvanathan’s son.

A metal sthapati shows us a wax mold that is being made for a Deity statue.

It’s 8:00pm, and the mold is hot. The embers are removed, and every trace of the embers is swept out of the mold. It should be completely clear of debris when the metal goes in.

A funnel is then put into place on top of the mold both to contain the heat so the metal doesn’t cool too fast and to contain splashes and flames that could hurt the workers.

Finally, the first ceremonial cup of metal is ready. Yoginathaswami places two gold coins into the red-hot and flaming cup of liquid, which disappear instantly. It is mixed for a moment and then carefully poured through a hole in the funnel.

Then began the process of packing the rest of the metal into the ceramic melting pots. They had gathered all of the metal previously, weighed it and sorted it so that each pot of molten metal would have the same ratio of brass to copper.

They had about 20 men there for this work. And it is very hard work. Everyone was running around busily, installing heat shields to protect the wood and tin roof above the outdoor, open-air forging pits, preparing hot coals, bringing in enormous amounts of metal, packing the pots, installing the funnel over the mold, installing a tent over the mold to block the rain that was coming (hmmm, another thunderstorm!).

Hot coals were placed in the bottom of the two forging fire pits. Finally the sixteen pots full of metal (a huge amount) were finished being packed, very tightly, and were lowered into the pits. Bags and bags of coal were poured in to surround the pots, and an overflow of old metal pots which would also be used in a second round were placed on top of each array of melting pots with a big sheet of metal to contain the heat. The blowers were started. Later, the fires were raging, quite colorfully because of all the different kinds of metal. At about 10:30pm we departed, having done our ceremonial part and witnessed most of the process.

The next morning we returned to check the progress, and we learned that it took up until 2:00am. Casting is always done at night because the whether is cooler then. As the process is a very hot one, it would be unbearable to do during a hot South Indian day any time of the year. Here is the funnel, now quite a different color. The red splotches on top are from turmeric water that was sprinkled on the funnel to purify the atmosphere during the casting. The heat turned the turmeric red. You can also see some metal on top of the hole that was used for pouring. We broke off a piece to bring home.

From Our Gurus' Teachings

Archives are now available through 2001. Light colored days have no posts. 1998-2001 coming later.